Small domestic wastewater treatment plants (WWTPs) are designed for biological-mechanical treatment of municipal wastewater. Biological wastewater treatment plants enable septic tank or cesspool replacement, therefore, they are most often used for the treatment of sewage water from family houses, guesthouses or cottages. The AS-VARIOcomp K home water purifier is the most suitable for the family home, with its main advantages being minimal operating costs and fast return on investment.

As in other industries, if you want to find a professional solution, the most effective one is probably not going to be a one-size-fits-all solution.

That is why we are ready to provide you with a complete professional implementation service.

AS-MONOcomp

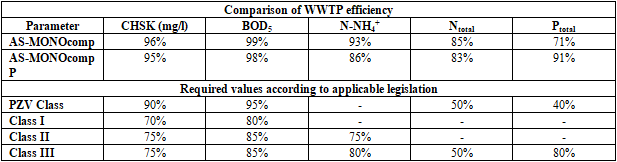

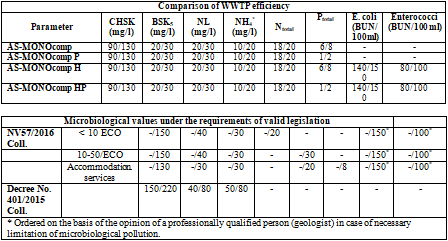

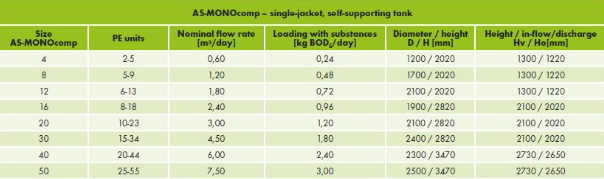

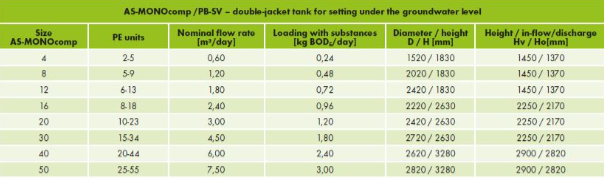

The AS-MONOcomp wastewater treatment plant is designed for the treatment of municipal wastewater. SBR-type WWTP with a cleaning process or blower operation controlled by an electric microprocessor control unit, optionally with a phosphorus precipitation device and/or with a UV lamp at the outlet for hygienisation of the treated water. It is a certified product with simple installation, easy operation and a real solution to the sludge problem – a WWTP with disposal of excess sludge by means of an integrated dewatering device, which ensures the extraction of excess sludge into a separate sludge area and its stabilisation for the possibility of subsequent composting (4-16 EO) or removal from an external sludge tank (20-50 EO). This WWTP in several variants for 2-50 EO meets the requirements for WWTP class III according to NV 401/2015 Coll., category PZV and limits of microbiological pollution according to NV 57/2016 Coll.

Variants of the AS-MONOcomp WWTP

The AS-MONOcomp wastewater treatment plant can be supplied in 4 different variants according to the requirements for the parameters of the treated water:

– Type AS-MONOcomp

Standard version of the treatment plant without phosphorus precipitation and effluent sanitation equipment.

– Type AS-MONOcomp P

Standard version of the treatment plant with phosphorus precipitation equipment, but without equipment for hygienisation of the effluent water.

– Type AS-MONOcomp H

The standard version of the treatment plant with the addition of a device for hygienisation of the effluent water, but without the device for phosphorus precipitation.

– Type AS-MONOcomp HP

Standard version of the treatment plant with phosphorus precipitation and effluent sanitation equipment.

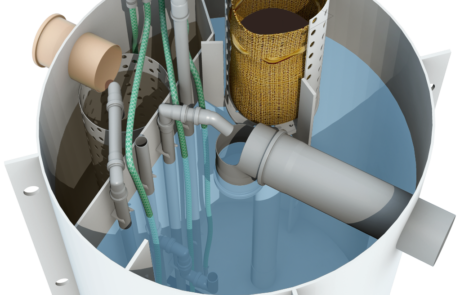

AS-MONOcomp – technology description

The wastewater flows through the influent basket into the influent part of the SBR reactor of the WWTP, where the influent is calmed and mechanical impurities are partially separated. The effluent in the SBR reactor is subject to a treatment process that uses a controlled treatment cycle that takes place during the day and alternates between aeration, sedimentation, flushing, effluent and sludging phases. During the aeration phase, the tank is filled and aerobic cleaning processes take place simultaneously. The floating micro-organisms clustered in flakes remove organic pollution by aerobic degradation and convert it into biomass. Sedimentation of the flakes is ensured by creating an interface between the activated sludge and the treated water. Flushing prevents unwanted dissolved solids from being carried down the drain. The treated water is then drained into a drainage trough. Excess sludge generated in the WWTP is eventually pumped to a dewatering facility for sludge stabilisation and subsequent disposal.

Advantages of the wastewater treatment plant AS-MONOcomp wastewater treatment plant

• Reliable, proven tank design with several variants

• WWTP for groundwater and surface water permits

• Simple technology with proven high reliability and efficiency

• Sludge issues solved by low-cost disposal

• Variants with phosphorus precipitation and/or effluent sanitation

• Possibility to use treated water for irrigation

• Possibility of remote monitoring of the WWTP

• Inlet stack included, inlet manhole cover, blower and control unit

• Advantageous price for PZV type WWTP on notification

• Low operating costs

• Customer support and service throughout the country

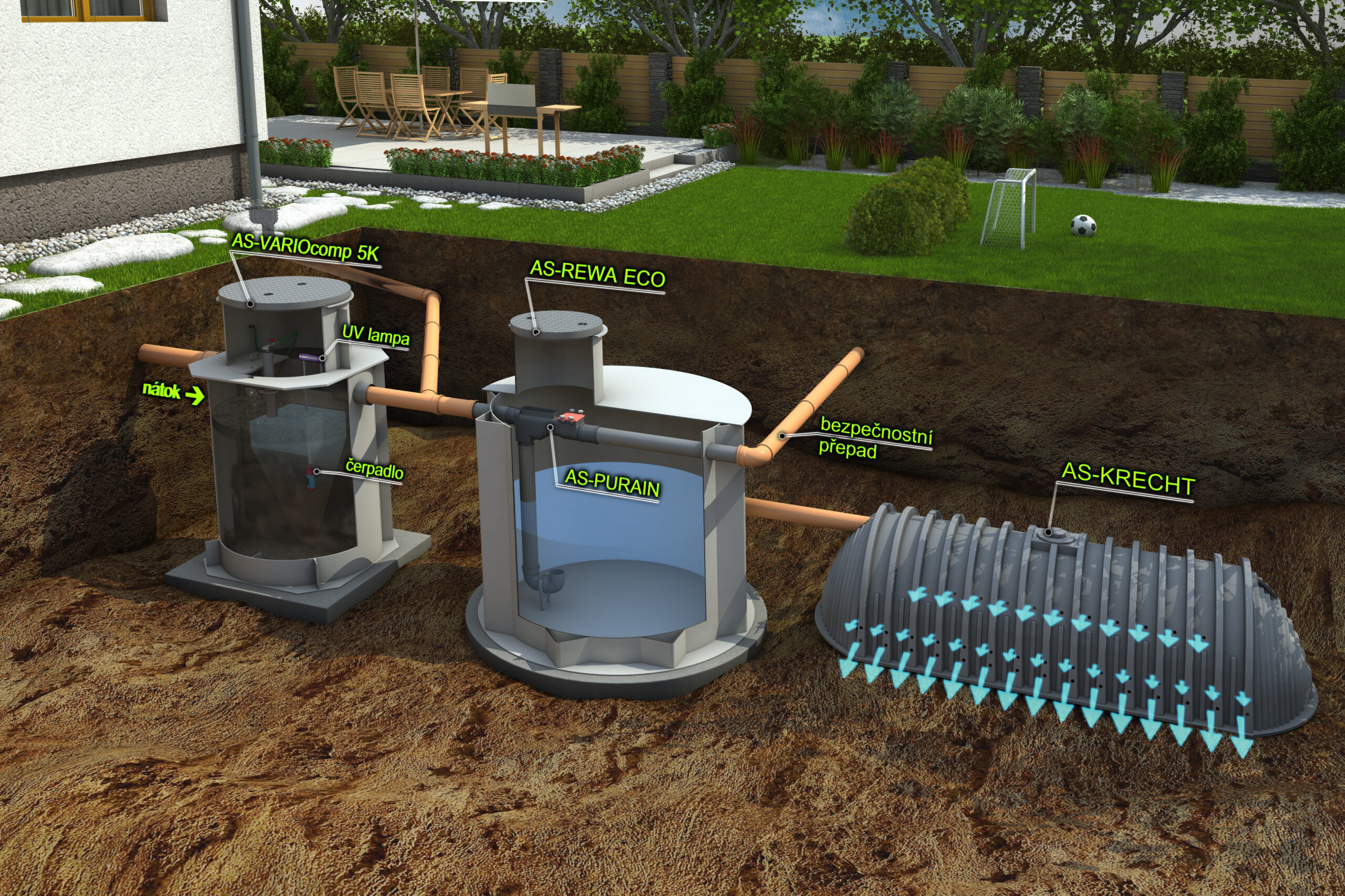

Installation of the ČOV

The installation is simple – the tank is installed in a trench on a concrete slab, connected to the sewerage system and connected via hoses in the protection box to the control unit (and blower), which is connected to the electricity – 230 V.

Sampling from the WWTP

In the case of using the WWTP within the framework of the classical water permit procedure, we recommend installing a review and sampling point or an AS-REVO shaft for sampling behind the WWTP. It is then possible to take samples as a one-off.

Other options

• Monitoring of wastewater treatment plants using AS-GSM – allows to monitor the operation and inform the owner via SMS about faults and operating conditions.

• Equipment for dosing of artificial nutrition in case of longer-term lower wastewater load.

• It is possible to purchase a freestanding pillar or a wall cabinet for the blower and control unit.

AS-VARIOcomp K

Type series of equipped domestic sewage treatment plants designed to treat sewage water from houses. The technological solution of these treatment plants is based on stable and reliable operation with minimum energy consumption. This technology uses aerobic biological processes that have been proven in practice over many years of operation.

DESCRIPTION OF TECHNOLOGY Advantages of AS-VARIOcomp K

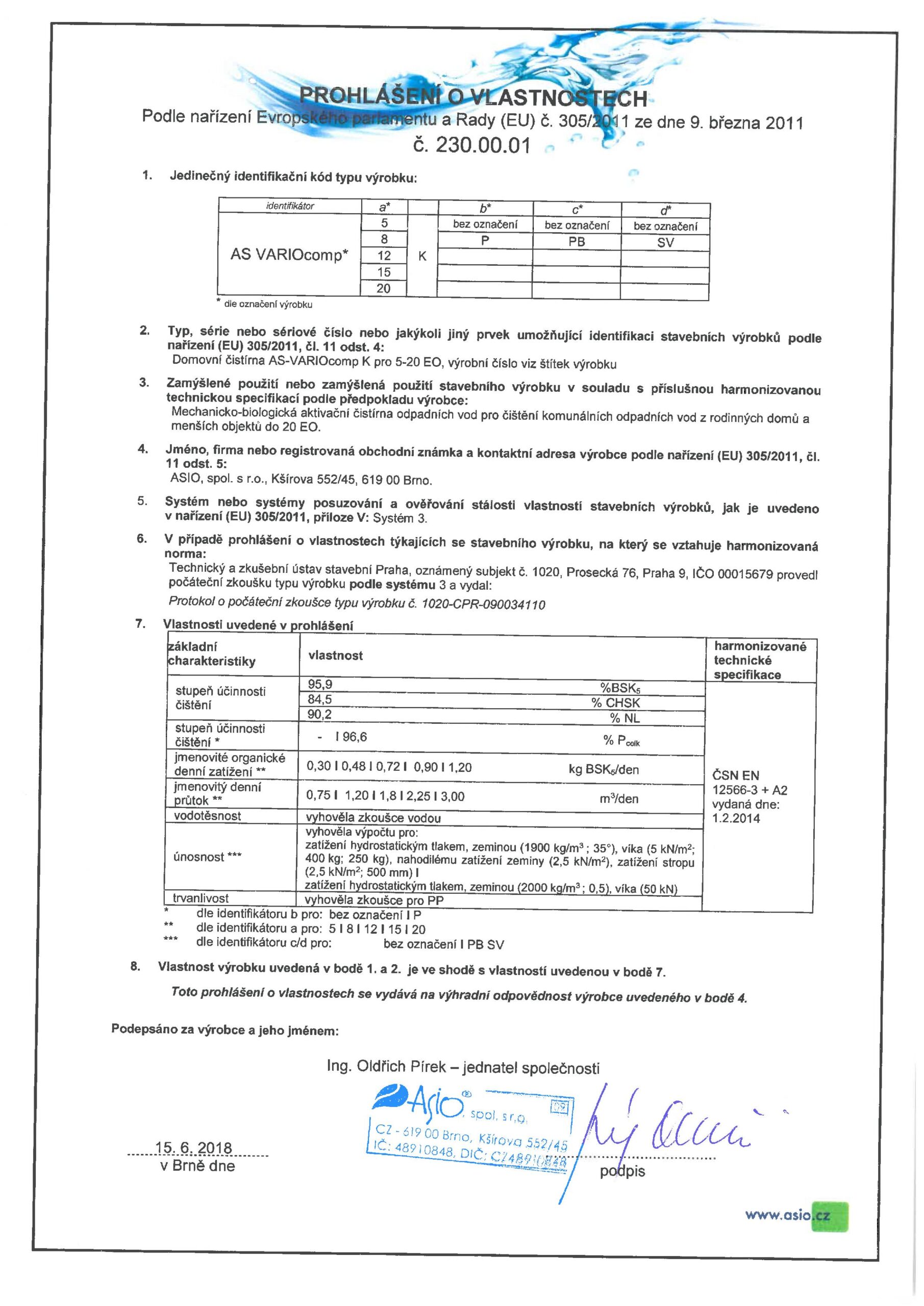

• Certification according to EN 12566-3/A2

• Low operating costs

• Completeness of delivery (all included)

• Walk-in hatch

• Easy handling and operational reliability

• Customer support and service throughout the country

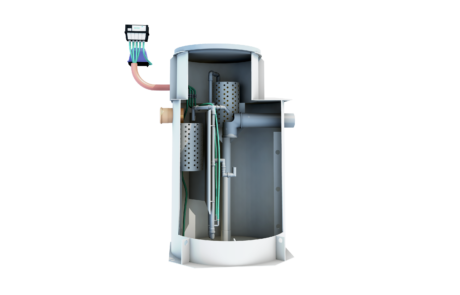

The wastewater flows into the settling area (A) of the influent part of the WWTP, where it is stripped of mechanical floating and settling substances, which are further subjected to anaerobic decomposition. From the settling area, the mechanically pre-treated water flows through the overflow into the activation area (B).

The activation area (B) is used for biological treatment of wastewater. This space is equipped with a fine-bubble aeration system at the bottom, into which air is blown by a blower, and possibly a biomass carrier (C) to improve the stability of the process of an overloaded or underloaded WWTP. The advantage of the solution is the accumulation space (D) in the entire area of the treatment plant, which is designed to accumulate wastewater and to ensure the uniformity of the outflow from the treatment plant. The activated mixture from the activation flows into the vertical settling tank (E), from where the treated water is then drawn off through the mammoth (F) into the outlet trough. Excess aerobically stabilised sludge is drawn off by means of a mammoth to the settling and sludge compartment (A) as required.

The treatment plant has undergone an additional verification test of efficiency under the supervision of the “Technical and Testing Institute of Construction Prague, s.p.”. During the test, the basic efficiency parameters including ammonia and phosphorus were verified, thus proving compliance with the requirements of National Decree No. 57/2016 Coll., “on indicators and values of permissible pollution of wastewater and the requirements for the permit for the discharge of wastewater into groundwater”. The values measured in the original type test measurement and the values of the additional verification test show that the WWTP can be used:

• for the water permit procedure – also for discharge to groundwater – see guaranteed values,

• for notification – as a Class I WWTP.

Installation of treatment plants

The water treatment plant is installed in an excavation pit on a concrete base plate (concrete encasement is not necessary), connection by joining pipes to the sewer system and air connection from a blower that is placed outside the water treatment plant. Setting of individual functions is done by the manufacturer; except for the connection of the blower in the socket, the water treatment plant does not require any additional wiring works. Commissioning of the water treatment plant is done by the supplier of an authorised servicing company. Owing to the dimensions and the weight, the types for 5 and 8 EO are transportable by a trailer; placement in an excavation pit is possible without a crane.

AS-GSM – Wastewater treatment plant monitoring

In order to control the proper functioning of wastewater treatment plant processes, our company has developed monitoring devices that will eliminate accidents and, in the case of membrane WWTPs, inform about the impending need to replace (regenerate) membranes by alerting the operator in time. The newly offered variants are based on the system of information transmission over GSM networks using SMS messages.

Statics

The statics of the tanks is designed by finite element method using the NEXIS calculation program for a load capacity of 25 years.

Copyright Pagroma